Chassis design for enhanced stability

The chassis forms the foundational structure of any vehicle, acting as its skeleton. Its intricate design is paramount for ensuring not only the structural integrity of the automobile but also its dynamic performance, especially concerning stability. A well-engineered chassis is crucial for a vehicle's ability to handle various road conditions, respond predictably to driver inputs, and maintain occupant safety, making it a central focus in automotive engineering and development.

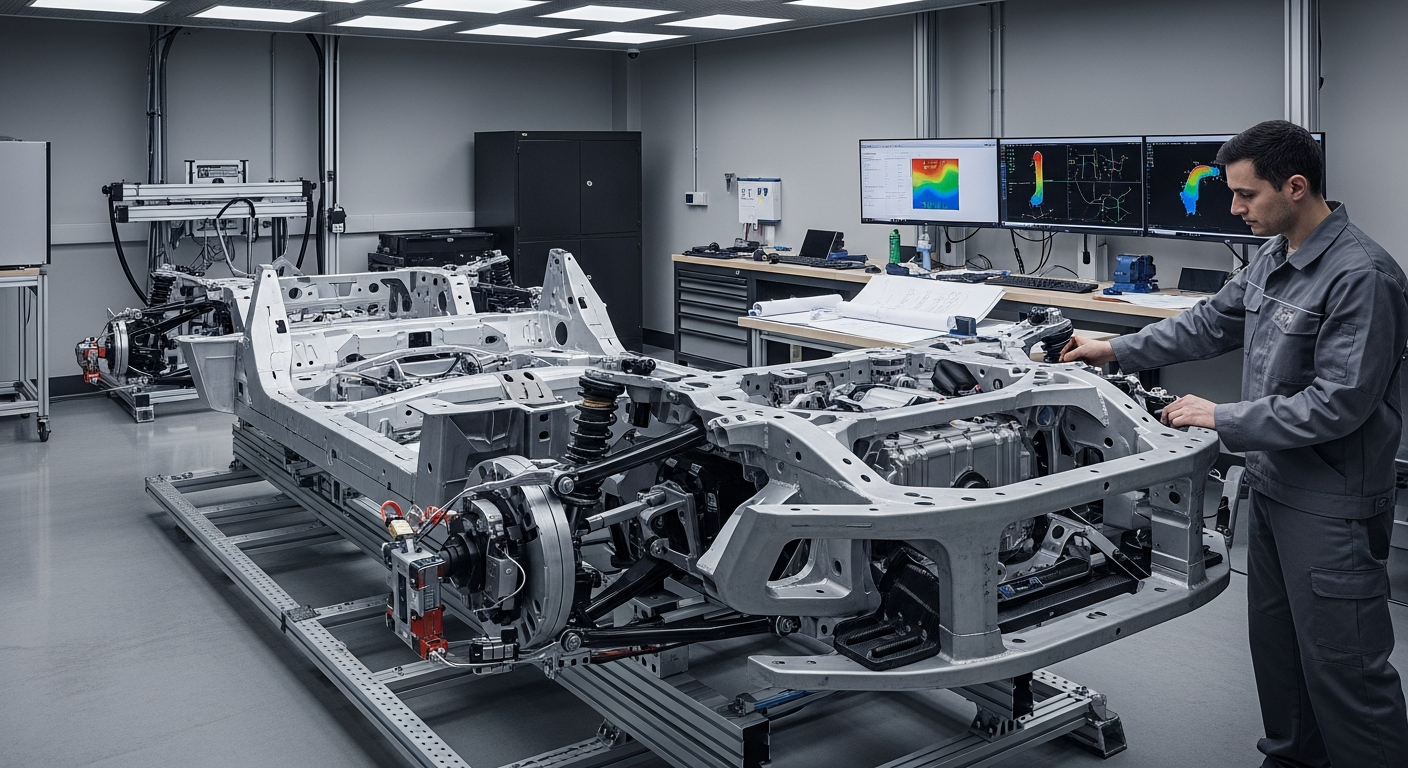

Understanding the Fundamentals of Chassis Design and Vehicle Mechanics

The chassis serves as the backbone of a vehicle, supporting the body, engine, transmission, and other essential components. Its primary function extends beyond mere support; it significantly influences the vehicle’s overall performance, handling, and ultimately, its stability. The fundamental design principles involve creating a rigid yet flexible structure that can withstand various stresses, including torsional forces during cornering, longitudinal forces during acceleration and braking, and vertical forces from road imperfections. Engineers meticulously consider material science, structural geometry, and weight distribution to optimize these characteristics. The mechanics of how a chassis interacts with suspension systems, steering, and braking are complex, with each element contributing to the vehicle’s ability to maintain equilibrium and control during driving.

Key Components and Their Role in Enhancing Vehicle Stability and Safety

Several key components are integral to a chassis’s ability to deliver enhanced stability and occupant safety. The frame, whether a ladder, monocoque, or spaceframe design, provides the primary structural rigidity. Suspension systems, comprising springs, shock absorbers, and linkages, manage tire contact with the road, absorbing impacts and controlling body roll, pitch, and heave. Steering components enable precise control, while braking systems are crucial for controlled deceleration. Modern chassis incorporate advanced components like anti-roll bars, stabilizer links, and sophisticated bushing materials, all meticulously designed to improve the vehicle’s dynamic response. The strategic placement and integration of these components are vital for predictable handling and maintaining stability, particularly in challenging driving scenarios, thereby directly contributing to overall safety on the road.

Innovations and Technology Advancements in Modern Chassis Design

Innovation in chassis design is an ongoing process, driven by advancements in materials, manufacturing techniques, and computational modeling. High-strength steel, aluminum alloys, and carbon fiber composites are increasingly used to reduce weight while improving rigidity, leading to better fuel efficiency and enhanced performance. Advanced simulation software allows engineers to test countless design iterations virtually, optimizing stress distribution and predicting real-world behavior before physical prototypes are even built. Furthermore, active chassis technologies, such as adaptive suspensions and active steering systems, utilize sensors and electronic control units (ECUs) to dynamically adjust vehicle parameters in real-time, significantly improving stability, comfort, and driving dynamics across various conditions. These technological leaps are transforming the landscape of mobility and transport.

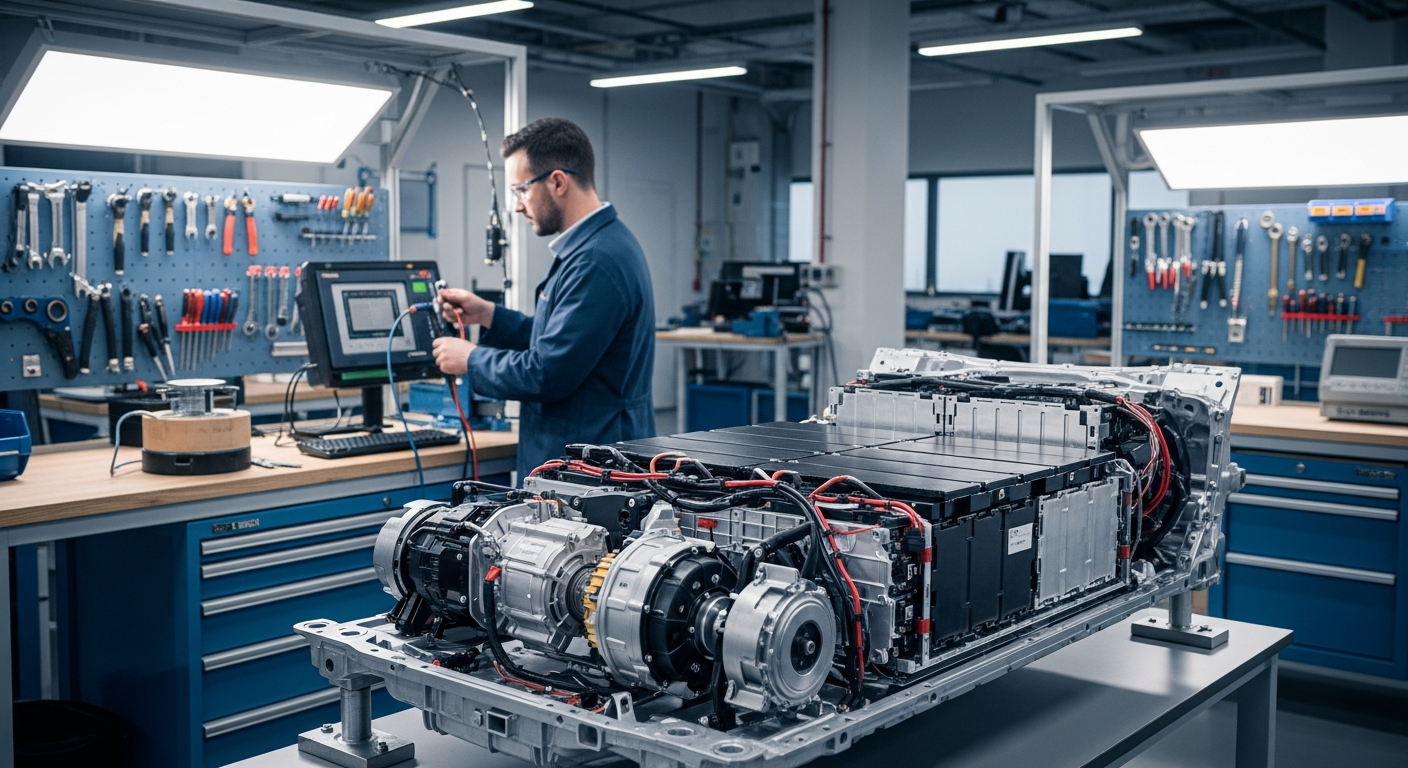

Chassis Adaptation for Diverse Powertrains: Electric, Hybrid, and Fuel Vehicles

The advent of electric and hybrid vehicles has brought new considerations for chassis design. Unlike traditional fuel-powered vehicles with internal combustion engines, electric vehicles (EVs) often house heavy battery packs within the chassis, typically located in the floorpan. This low and centralized weight distribution inherently contributes to a lower center of gravity, which can enhance stability. Hybrid vehicles, combining electric motors with conventional engines, also require careful packaging and weight management within the chassis structure. Designers must account for the unique thermal management requirements of batteries and electric motors, as well as the crash protection needed for high-voltage components. The chassis must be adaptable to different engine and powertrain configurations while maintaining structural integrity and dynamic performance, ensuring that whether a vehicle runs on petrol, diesel, or electricity, its underlying structure provides a stable and safe driving experience.

Manufacturing Processes and Chassis Design for Varied Road and Urban Environments

Manufacturing processes play a critical role in realizing complex chassis designs. Techniques like advanced welding, laser cutting, and robotic assembly ensure precision and consistency in production. The choice of manufacturing method impacts the structural integrity and cost-effectiveness of the chassis components. Furthermore, chassis design must consider the diverse road and urban environments vehicles operate in. For instance, vehicles designed for urban logistics might prioritize maneuverability and durability for frequent stops and starts, while those intended for long-haul transport on open roads emphasize stability at higher speeds and load-bearing capacity. The integration of automation in manufacturing has further refined the quality and efficiency of chassis production, allowing for greater customization and robustness tailored to specific usage conditions and regional requirements. This adaptability is key for modern driving needs.

Chassis design is a multifaceted engineering discipline that underpins the entire vehicle experience. From the foundational mechanics to the integration of cutting-edge technology and adaptation for diverse powertrains, every aspect contributes to a vehicle’s stability, safety, and overall performance. Continuous innovation in materials, manufacturing, and electronic systems ensures that chassis designs evolve to meet the demands of modern mobility, offering drivers and passengers enhanced control and confidence on the road.