Exploring advanced propulsion systems

Advanced propulsion systems represent a significant evolution in how vehicles are powered, moving beyond conventional internal combustion engines towards more efficient and environmentally conscious solutions. This shift is driven by a global push for reduced emissions, enhanced performance, and a more sustainable future for transport. Understanding these complex systems involves delving into various technological advancements, from new energy sources to integrated digital controls, all contributing to a transformative era in automotive engineering and mobility.

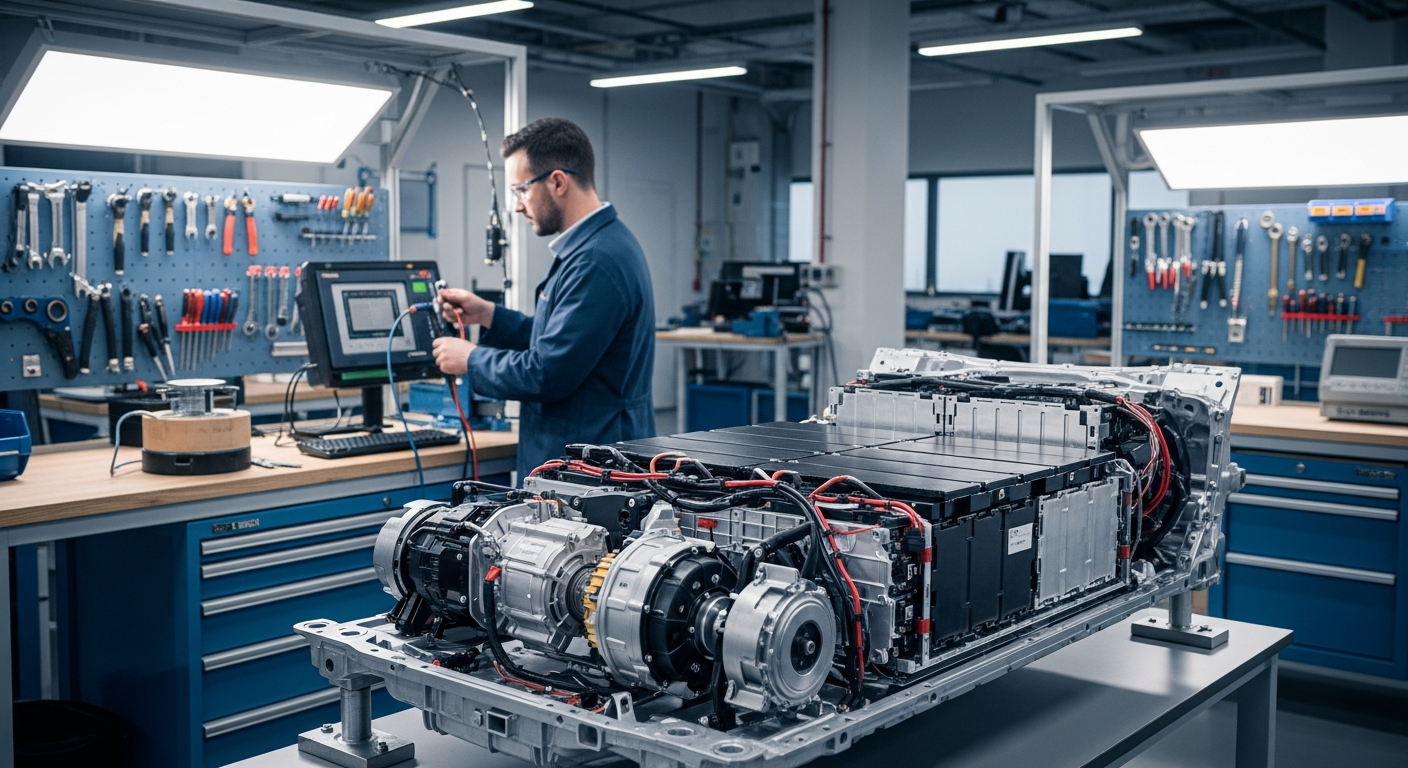

Propulsion and Electrification Advancements

The landscape of vehicle propulsion is undergoing a profound transformation, with electrification at its core. Traditional internal combustion engines (ICEs) are steadily being complemented and, in many cases, replaced by electric powertrains. This includes a spectrum of technologies: hybrid electric vehicles (HEVs) that combine an ICE with an electric motor; plug-in hybrid electric vehicles (PHEVs) offering greater electric-only range; and fully battery electric vehicles (BEVs) that rely solely on electric power. Furthermore, fuel cell electric vehicles (FCEVs), which generate electricity from hydrogen, are emerging as a promising zero-emission alternative, particularly for heavier transport applications. These systems aim to improve energy efficiency, reduce fuel consumption, and significantly lower tailpipe emissions, addressing critical environmental concerns globally.

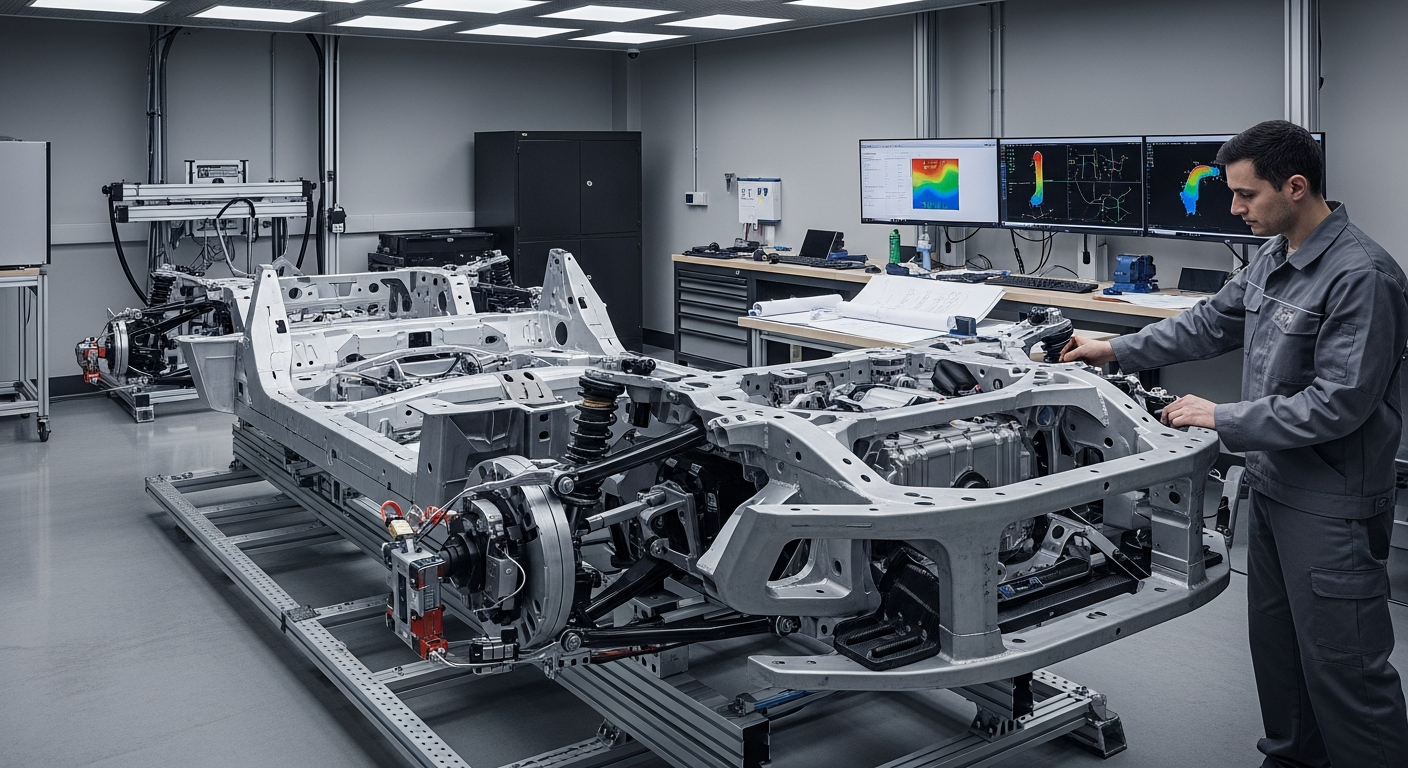

Engineering and Materials for Enhanced Efficiency

The development of advanced propulsion systems is intrinsically linked to breakthroughs in engineering and materials science. Modern vehicle design prioritizes lightweight construction to offset the weight of battery packs and other new components, thereby improving range and performance. Materials such as high-strength steel, aluminum alloys, and carbon fiber composites are increasingly integrated into chassis and body structures. This focus on lightweighting, combined with sophisticated aerodynamic design, minimizes drag and optimizes energy use. Advanced manufacturing techniques, including additive manufacturing, also play a role in creating complex, optimized components that might be difficult to produce using traditional methods, further pushing the boundaries of vehicle efficiency and structural integrity.

Sustainability and Future Mobility Paradigms

Sustainability is a key driver behind the exploration of advanced propulsion systems. The goal is to create transport solutions that minimize environmental impact throughout their lifecycle, from manufacturing to end-of-life recycling. This extends beyond just tailpipe emissions to encompass the entire energy supply chain, including the source of electricity for charging and the production of hydrogen. The integration of advanced propulsion systems supports the broader concept of future mobility, which envisions interconnected, shared, and autonomous transport networks. These systems are crucial for achieving ambitious climate targets and for developing urban environments that are less reliant on fossil fuels, fostering cleaner air and quieter streets.

Safety, Dynamics, and Autonomous Integration

Advanced propulsion systems significantly influence vehicle safety and dynamic performance. Electric powertrains, for example, can offer instant torque delivery and precise power control, which can be leveraged for enhanced traction control and stability systems. The placement of heavy battery packs often results in a lower center of gravity, improving handling characteristics. Moreover, these systems are deeply integrated with advanced driver-assistance systems (ADAS) and emerging autonomous driving technologies. The digital control over propulsion, braking, and steering allows for sophisticated algorithms to manage vehicle movement, contributing to active safety features that can prevent accidents and improve overall driving dynamics. Robust braking systems are essential to manage the increased weight of some electrified vehicles and to incorporate regenerative braking capabilities, which convert kinetic energy back into electrical energy.

Digital Integration, Connectivity, and Cybersecurity

The evolution of advanced propulsion systems is inseparable from digital technology. Modern vehicles are essentially connected computers on wheels, with propulsion systems managed by complex electronic control units (ECUs) and sophisticated software. Connectivity features allow for over-the-air updates, remote diagnostics, and integration with smart infrastructure, enhancing both performance and user experience. However, this increased digital reliance also brings cybersecurity to the forefront. Protecting these systems from unauthorized access and malicious attacks is paramount to ensuring vehicle safety, data privacy, and the integrity of the transport network. Robust cybersecurity measures are critical for maintaining trust in connected and autonomous vehicles.

Economic Considerations for Advanced Propulsion Systems

The transition to advanced propulsion systems involves substantial economic investment across the automotive industry and related sectors. Research and development costs for new battery technologies, electric motors, power electronics, and fuel cell stacks are significant. Manufacturing facilities require retooling and upgrades to produce these new components and assemble electrified vehicles. Furthermore, the development of charging infrastructure for electric vehicles and hydrogen fueling stations for FCEVs represents a massive investment challenge and opportunity. While the initial purchase price of some advanced propulsion vehicles might be higher than their conventional counterparts, potential savings on fuel and maintenance, along with government incentives, can influence the total cost of ownership over time. The economic landscape is dynamic, shaped by technological progress, raw material costs, and global market demand.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Maintenance in the Era of Advanced Propulsion

Maintenance practices for vehicles equipped with advanced propulsion systems differ considerably from those for traditional ICE vehicles. Electric vehicles, for instance, typically have fewer moving parts, which can lead to reduced maintenance requirements for components like oil changes, spark plugs, and exhaust systems. However, specialized knowledge and equipment are necessary for servicing high-voltage battery systems, electric motors, and complex power electronics. Diagnostic tools have evolved to interface with sophisticated vehicle software, requiring technicians to have updated training in electrical systems, software diagnostics, and thermal management for batteries. Regular software updates also play a crucial role in maintaining optimal performance and efficiency for these advanced vehicles, highlighting a shift towards more digitally-driven service models.