Enhancing Efficiency in Commercial Operations

Modern commercial operations face constant pressure to perform optimally, reduce waste, and deliver value efficiently. Achieving this requires a holistic approach that integrates strategic planning with operational excellence across all facets of an enterprise. From the initial stages of manufacturing to the final delivery of goods and services, understanding and implementing efficiency-driven practices is crucial for sustained success and competitiveness in today's dynamic global markets. This article explores key strategies and technological advancements that businesses can leverage to streamline their processes and foster significant improvements.

Commercial operations, spanning various industries, are continually seeking ways to optimize their workflows, minimize resource consumption, and maximize output. The pursuit of enhanced efficiency is not merely about cost reduction; it is fundamental to an organization’s ability to innovate, adapt, and thrive in competitive environments. By systematically addressing inefficiencies across the entire value chain, businesses can unlock significant potential for growth and market leadership.

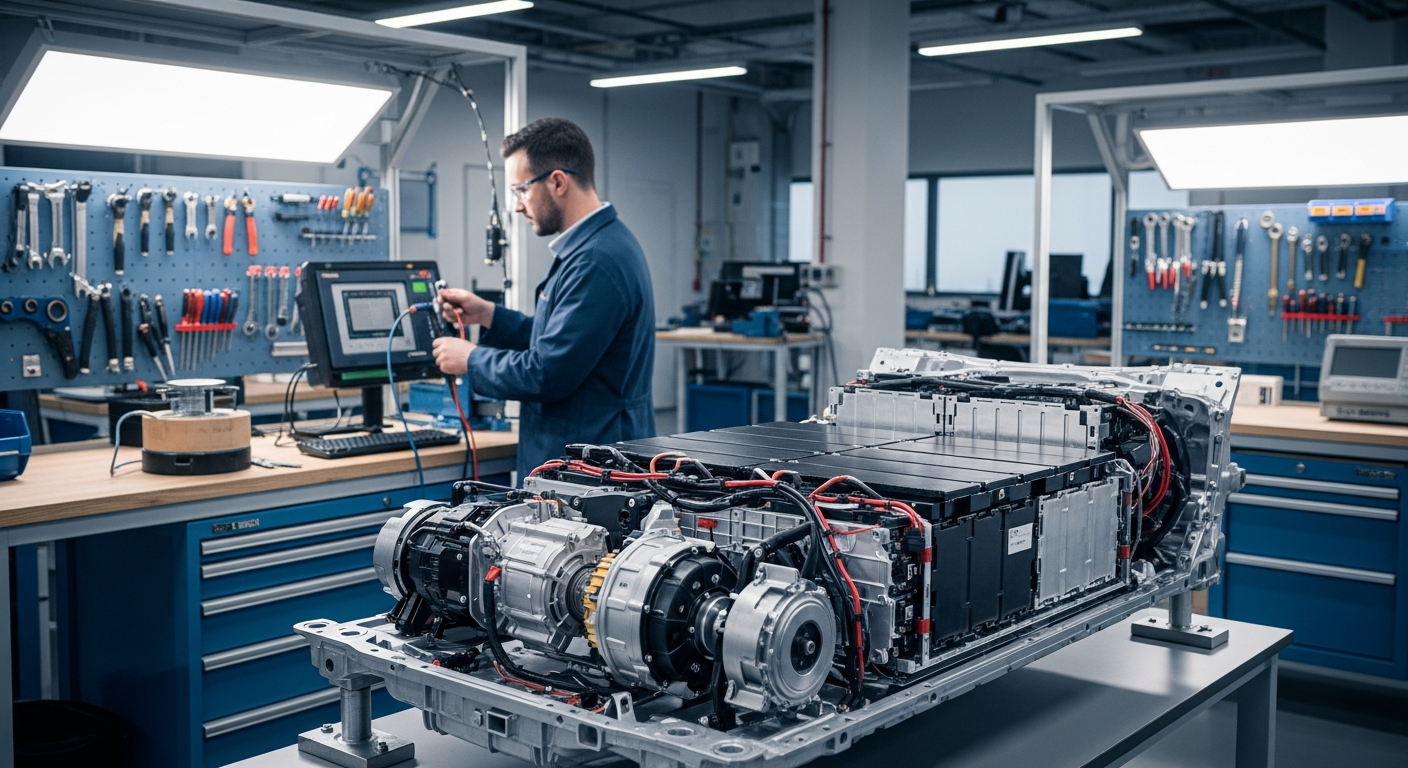

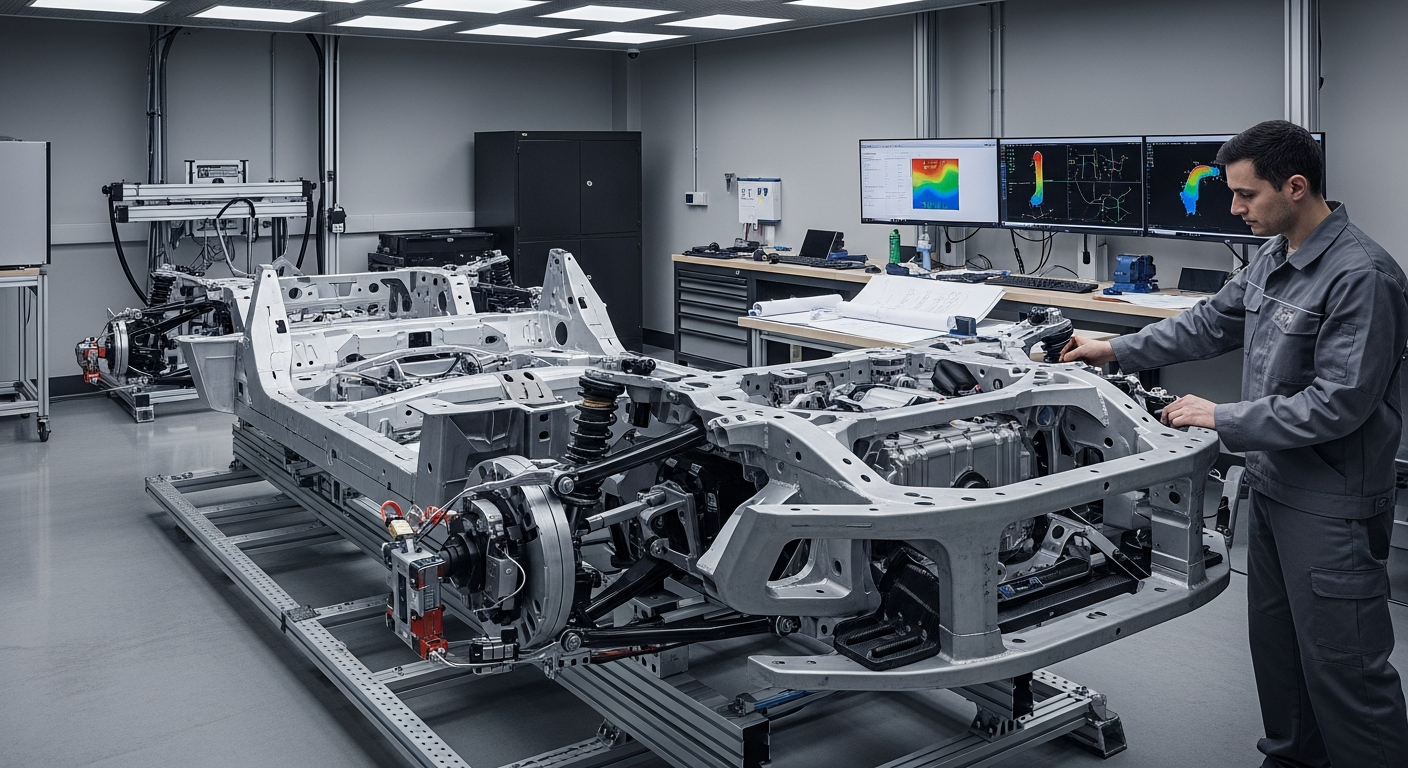

Optimizing Manufacturing and Production Processes

Refining core manufacturing and production workflows is a cornerstone of operational efficiency. Businesses often achieve this through the adoption of methodologies like Lean Manufacturing, which focuses on identifying and eliminating waste in all its forms, from overproduction to unnecessary motion and defects. Implementing techniques such as Six Sigma can further enhance process consistency, reduce variability, and minimize errors, leading to substantial cost savings and improved product quality. Effective inventory management, coupled with accurate demand forecasting, ensures that raw materials and finished goods are utilized efficiently, preventing both excessive stock holding and costly shortages. Continuous improvement initiatives foster a culture where every team member contributes to refining processes and enhancing overall output.

Leveraging Technology and Automation in Operations

The impact of digital transformation on operational efficiency cannot be overstated. Modern technology and automation tools are revolutionizing how businesses manage their operations. The Industrial Internet of Things (IIoT) enables real-time data collection from machines and processes, providing invaluable insights for predictive maintenance and performance optimization. Artificial Intelligence (AI) and Robotic Process Automation (RPA) can automate repetitive, rule-based tasks, freeing human capital for more complex and strategic work. These technologies not only boost efficiency and reduce human error but also provide granular data analytics that empower informed decision-making across various production and operational stages, leading to more agile and responsive enterprises.

Enhancing Logistics and Supply Chain Management

Effective logistics and supply chain management are critical for ensuring the smooth flow of goods and services from origin to customer. Strategies for enhancement include the adoption of integrated supply chain platforms that provide end-to-end visibility and control. Predictive analytics can optimize transportation routes, reduce fuel consumption, and minimize delivery times. Robust supplier relationship management is crucial for fostering strong partnerships, ensuring reliable supply, and mitigating risks. Emphasizing transparency and collaboration across the entire supply chain helps minimize disruptions, reduce operational costs, and ensures timely delivery, which is vital for commerce and customer satisfaction in a global market.

Cultivating Innovation for Enterprise Growth

A culture of innovation is a powerful driver for sustained growth and development within any enterprise. This involves more than just investing in research and development; it encompasses encouraging employee suggestions for process improvements, embracing new technologies, and adopting agile methodologies that allow for rapid prototyping and adaptation. Businesses that continuously seek new ways to deliver value, whether through product innovation or operational enhancements, are better positioned to respond to evolving market trends and consumer demands. This strategic approach helps maintain a competitive edge and secures long-term relevance in dynamic global markets.

Building Resilience and Sustainability in Industry

In an increasingly interconnected yet unpredictable world, building resilience in operations is paramount. This includes diversifying supply chains to reduce reliance on single sources, implementing robust risk management strategies to anticipate and mitigate potential disruptions, and developing contingency plans for various scenarios. Concurrently, the focus on sustainability has grown significantly. Adopting environmentally friendly practices in production, reducing waste, and optimizing energy consumption not only addresses ecological concerns but can also lead to long-term cost savings and an enhanced brand reputation. Sustainable industrial practices contribute to both planetary well-being and a more robust business model.

Investing in operational efficiency often requires upfront capital, but the long-term returns typically justify the expenditure through cost savings, increased productivity, and enhanced competitiveness. The cost of implementing efficiency-enhancing solutions varies widely depending on the scale of the enterprise, the complexity of the existing infrastructure, and the specific technologies or services chosen. For instance, a small business might invest in off-the-shelf software, while a large enterprise may opt for custom-built systems or comprehensive consulting engagements.

| Product/Service | Provider Type | Cost Estimation (USD) |

|---|---|---|

| Enterprise Resource Planning (ERP) Software | Mid-tier Software Vendors | $5,000 - $50,000/year |

| Supply Chain Management (SCM) Software | Specialized SCM Providers | $3,000 - $30,000/year |

| Robotic Process Automation (RPA) Solution | RPA Software & Consulting Firms | $10,000 - $100,000+ |

| Operational Efficiency Consulting | Management Consulting Firms | $150 - $500/hour |

| Data Analytics Platform | Business Intelligence Vendors | $1,000 - $15,000/month |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Enhancing efficiency in commercial operations is an ongoing journey that requires continuous evaluation, strategic investment, and a commitment to improvement. By focusing on optimizing manufacturing, embracing technological advancements, streamlining logistics, fostering innovation, and building resilience and sustainability, businesses can not only achieve their operational goals but also position themselves for sustained success and growth in an ever-evolving global marketplace.