Future-Proofing Supply Chains for Economic Shifts

Economic volatility, geopolitical tensions, and technological disruption are reshaping global commerce at an unprecedented pace. Organizations across all sectors face mounting pressure to build supply chains that can withstand sudden market changes, regulatory shifts, and unforeseen crises. The ability to anticipate, adapt, and thrive amid uncertainty has become a critical competitive advantage, requiring strategic investments in flexibility, visibility, and collaborative partnerships that extend beyond traditional boundaries.

Supply chains have evolved from simple linear processes into complex, interconnected networks spanning continents and industries. As economic conditions fluctuate and markets become increasingly unpredictable, organizations must fundamentally rethink how they source, produce, and deliver goods and services. Building resilient systems that can absorb shocks while maintaining operational continuity requires a holistic approach combining technology, talent, and strategic foresight.

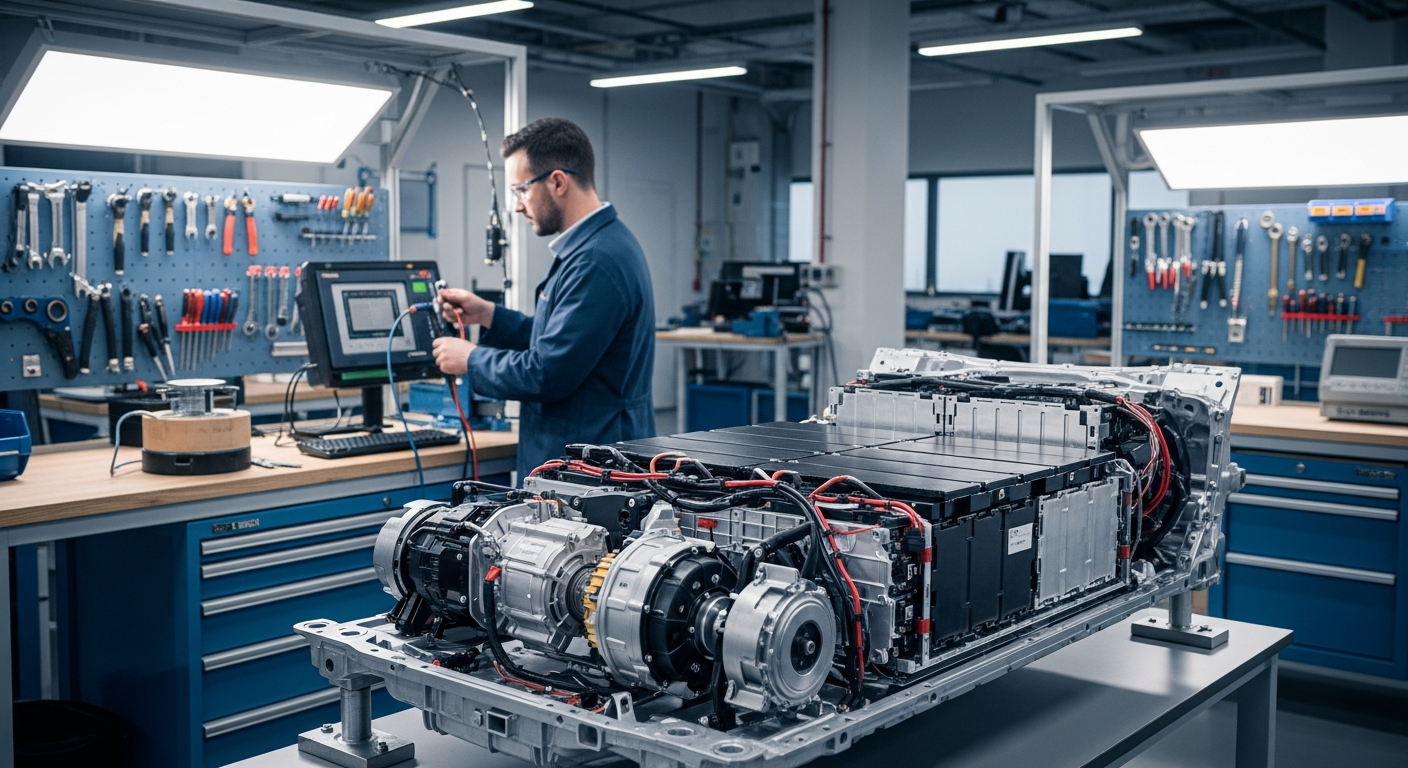

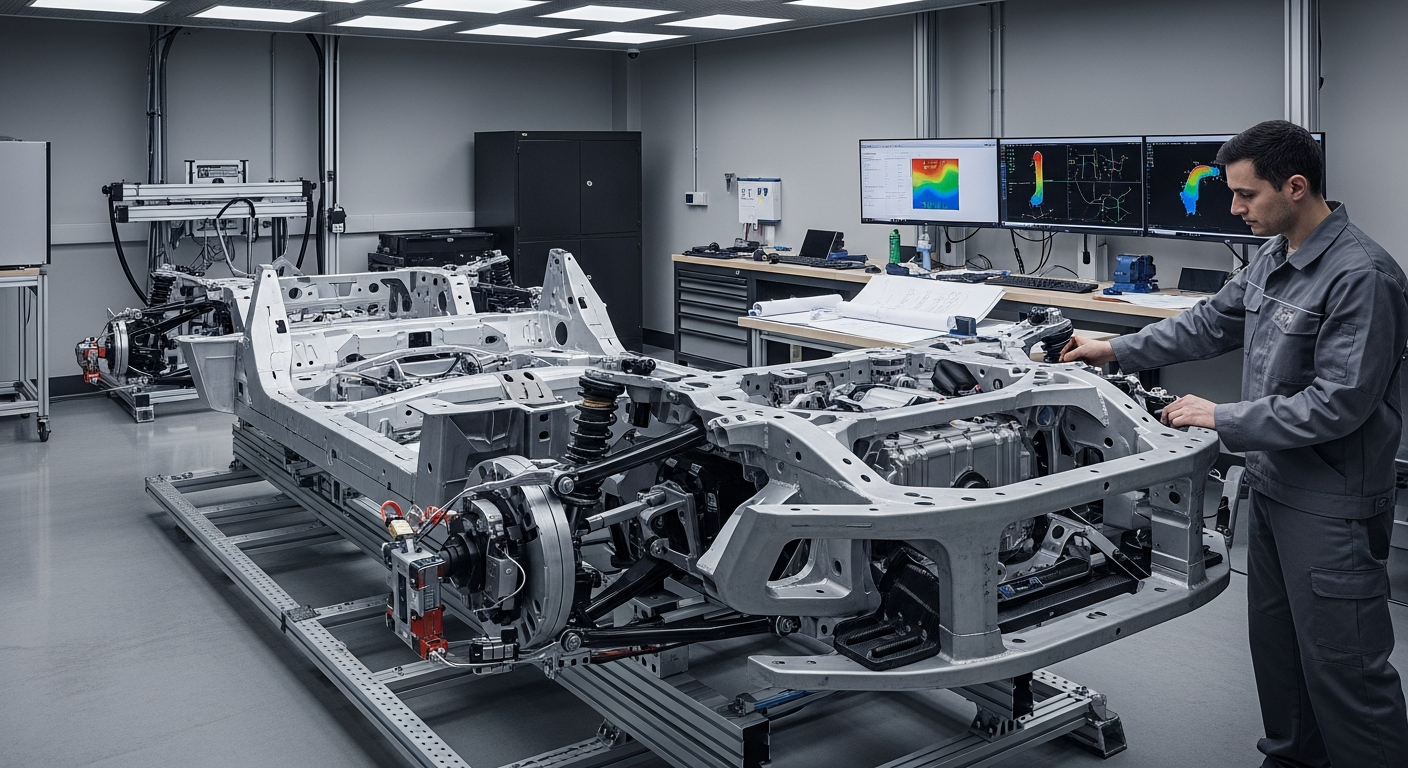

How Can Manufacturing Adapt to Economic Uncertainty?

Manufacturing operations face unique challenges during periods of economic instability, from fluctuating raw material costs to shifting consumer demand patterns. Successful adaptation begins with diversifying supplier bases to reduce dependency on single sources or geographic regions. Organizations are increasingly adopting nearshoring and regionalization strategies, bringing production closer to end markets to minimize transportation risks and lead times. Flexible production systems that can quickly switch between product lines enable manufacturers to respond rapidly to changing market conditions. Investment in modular equipment and cross-trained workforces creates the agility needed to scale operations up or down based on real-time demand signals. Advanced forecasting tools powered by data analytics help anticipate market shifts before they materialize, allowing proactive rather than reactive adjustments.

What Role Does Logistics Play in Supply Chain Resilience?

Logistics networks serve as the circulatory system of modern commerce, and their robustness directly impacts organizational resilience. Multi-modal transportation strategies reduce vulnerability to disruptions in any single channel, whether maritime, air, rail, or road. Building relationships with multiple carriers and freight forwarders provides alternatives when primary routes become compromised. Real-time tracking technologies offer unprecedented visibility into shipment locations and conditions, enabling rapid response to delays or quality issues. Warehouse network optimization ensures inventory is strategically positioned to serve customers efficiently even when primary distribution centers face disruptions. Collaborative logistics models, where organizations share transportation capacity and warehousing space, improve asset utilization while creating mutual support systems during crises.

How Can Digital Transformation Strengthen Operations?

Digital technologies fundamentally transform how organizations manage complexity and respond to change. Cloud-based platforms enable real-time collaboration across geographically dispersed teams and partners, breaking down information silos that slow decision-making. Artificial intelligence and machine learning algorithms process vast amounts of data to identify patterns, predict disruptions, and recommend optimal responses. Internet of Things sensors embedded throughout production facilities and logistics networks provide granular visibility into asset performance and environmental conditions. Digital twins—virtual replicas of physical systems—allow organizations to simulate scenarios and test strategies without risking actual operations. Blockchain technology creates transparent, tamper-proof records of transactions and product provenance, building trust among trading partners and enabling rapid verification during audits or investigations. Automation reduces dependence on manual processes that can become bottlenecks during labor shortages or demand surges.

What Strategies Enhance Supply Chain Efficiency?

Efficiency improvements free up resources that can be redirected toward resilience initiatives while reducing operational costs. Lean methodologies eliminate waste and streamline processes, creating smoother workflows that are easier to manage during disruptions. Just-in-time inventory approaches must be balanced with strategic buffer stocks of critical components to prevent stockouts during supply interruptions. Network optimization algorithms identify the most cost-effective configurations of facilities, transportation routes, and inventory positions. Standardization of processes and components across different facilities and product lines simplifies operations and enables rapid reallocation of resources when needed. Continuous improvement cultures encourage employees at all levels to identify inefficiencies and propose solutions, tapping into frontline expertise that management may overlook.

How Does Workforce Management Support Resilience?

People remain the most adaptable and creative element of any supply chain system. Cross-training programs ensure employees can perform multiple roles, providing flexibility when absences or demand spikes occur. Investing in employee development builds institutional knowledge and reduces turnover, preserving critical expertise. Remote work capabilities, where feasible, expand talent pools beyond geographic constraints and provide continuity options during facility disruptions. Collaborative relationships with temporary staffing agencies create surge capacity for peak periods or emergency situations. Strong safety cultures protect workforce health and reduce accident-related disruptions. Transparent communication during crises maintains morale and ensures everyone understands their role in recovery efforts.

What Is the Connection Between Sustainability and Resilience?

Sustainability initiatives often strengthen resilience as a secondary benefit. Energy efficiency improvements reduce exposure to volatile fuel costs and power supply disruptions. Circular economy approaches that emphasize reuse, remanufacturing, and recycling create alternative material sources when primary supplies are constrained. Local sourcing reduces transportation distances and associated risks while supporting regional economic stability. Water conservation and waste reduction programs decrease dependence on increasingly scarce natural resources. Carbon footprint reduction efforts often drive process innovations that improve overall efficiency and adaptability. Stakeholder expectations around environmental performance are rising, and organizations that proactively address sustainability concerns build stronger reputations and customer loyalty that provide buffers during difficult periods.

Conclusion

Building supply chains capable of withstanding economic shifts requires ongoing commitment rather than one-time projects. Organizations must balance efficiency with redundancy, global reach with local presence, and automation with human judgment. The most resilient systems combine technological capabilities with strong relationships, strategic foresight with operational flexibility, and cost consciousness with appropriate risk mitigation. As economic conditions continue to evolve, the organizations that invest in adaptable, transparent, and collaborative supply chain ecosystems will be best positioned to navigate uncertainty and capitalize on emerging opportunities.