Impact of Emerging Technologies on Industrial Output

Emerging technologies are fundamentally reshaping the landscape of global industrial output, driving significant transformations across various sectors. From advanced automation to sophisticated data analytics, these innovations are not merely incremental improvements but rather catalysts for profound shifts in how goods are produced, distributed, and managed. Understanding their multifaceted impact is crucial for businesses aiming to maintain competitiveness and foster sustainable growth in an evolving market.

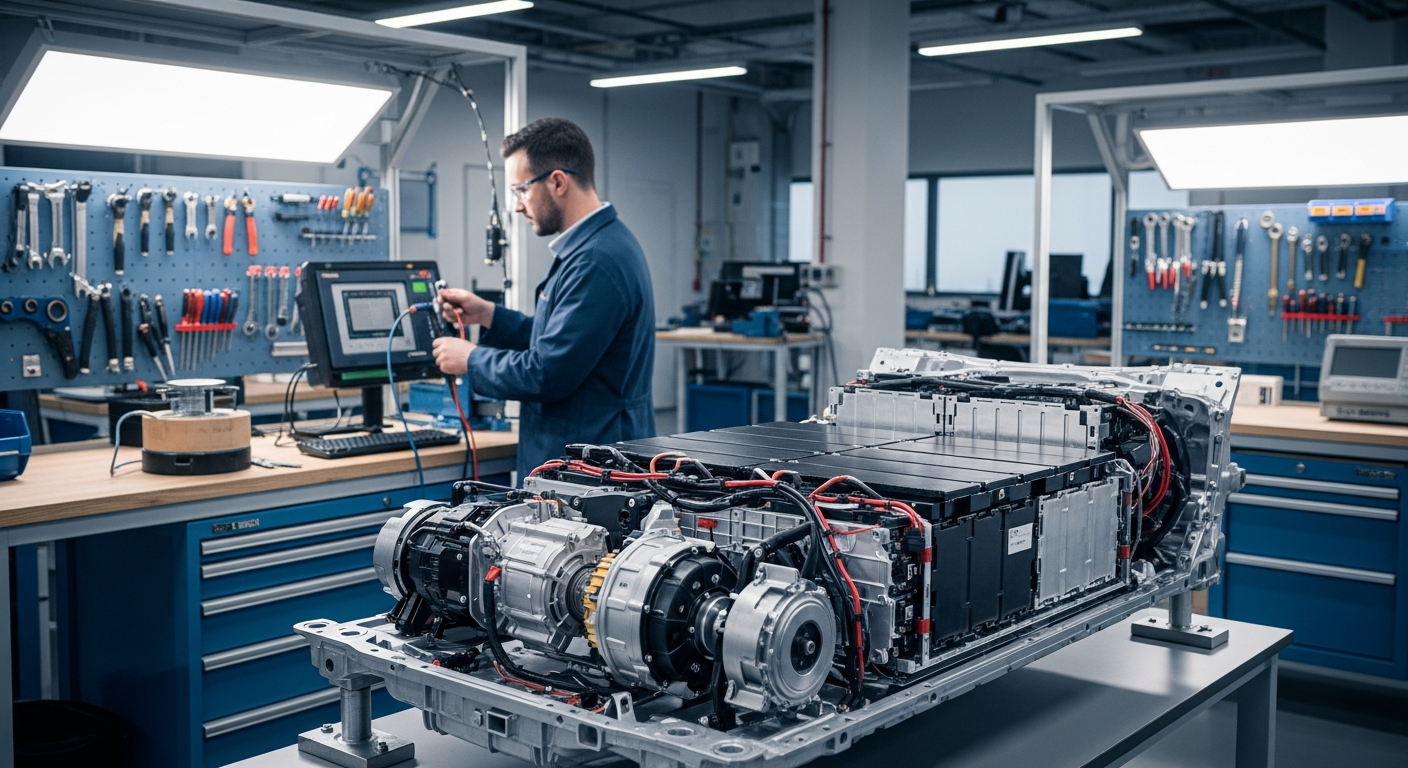

Automation and Advanced Manufacturing: Boosting Productivity

Automation stands as a cornerstone of modern industrial transformation, significantly enhancing manufacturing processes. The integration of robotics, cobots, and automated guided vehicles (AGVs) on production lines allows for continuous operation, reducing human error and increasing throughput. This technological advancement directly contributes to higher productivity levels, as tasks that were once time-consuming or labor-intensive can now be executed with greater speed and precision. Advanced manufacturing techniques, such as additive manufacturing (3D printing), further revolutionize production by enabling the creation of complex parts with reduced waste and faster prototyping cycles.

These automated systems contribute to a more streamlined production environment, minimizing bottlenecks and optimizing resource utilization. The ability to produce more goods in less time, with consistent quality, translates into substantial gains in overall industrial output. Enterprises embracing these methods often experience a competitive edge, allowing them to respond more agilely to market demands and scale operations effectively.

Data Analytics and AI in Industrial Operations

The proliferation of sensors and interconnected devices has led to an explosion of data within industrial settings. Leveraging this vast amount of information through advanced data analytics and artificial intelligence (AI) is critical for optimizing operations and enhancing efficiency. AI-powered algorithms can analyze real-time production data to predict equipment failures, identify inefficiencies, and recommend preventive maintenance, thereby reducing downtime and maintenance costs.

Predictive analytics allows management to make informed decisions, from inventory control to energy consumption, leading to significant improvements in operational efficiency. By uncovering patterns and insights that would be imperceptible to human analysis, these technologies enable continuous optimization across the entire value chain, directly impacting the quality and volume of industrial output. This data-driven approach fosters a culture of continuous improvement and strategic planning.

Reshaping Global Logistics and Supply Chain Management

Emerging technologies are profoundly transforming logistics and global supply chain management, making them more resilient and responsive. Technologies like blockchain offer enhanced transparency and traceability, allowing for real-time tracking of goods from origin to destination. This visibility helps mitigate risks, verify product authenticity, and improve accountability across complex supply networks. Furthermore, the use of AI for demand forecasting and route optimization significantly enhances the efficiency of goods movement.

Automated warehousing solutions, including robotic picking and packing systems, accelerate order fulfillment and reduce operational costs. The ability to manage intricate logistics more effectively facilitates smoother trade flows and ensures products reach global markets more reliably and quickly. This technological integration strengthens the overall supply chain, making it more adaptable to disruptions and supportive of sustained industrial growth.

Driving Innovation and Enterprise Growth

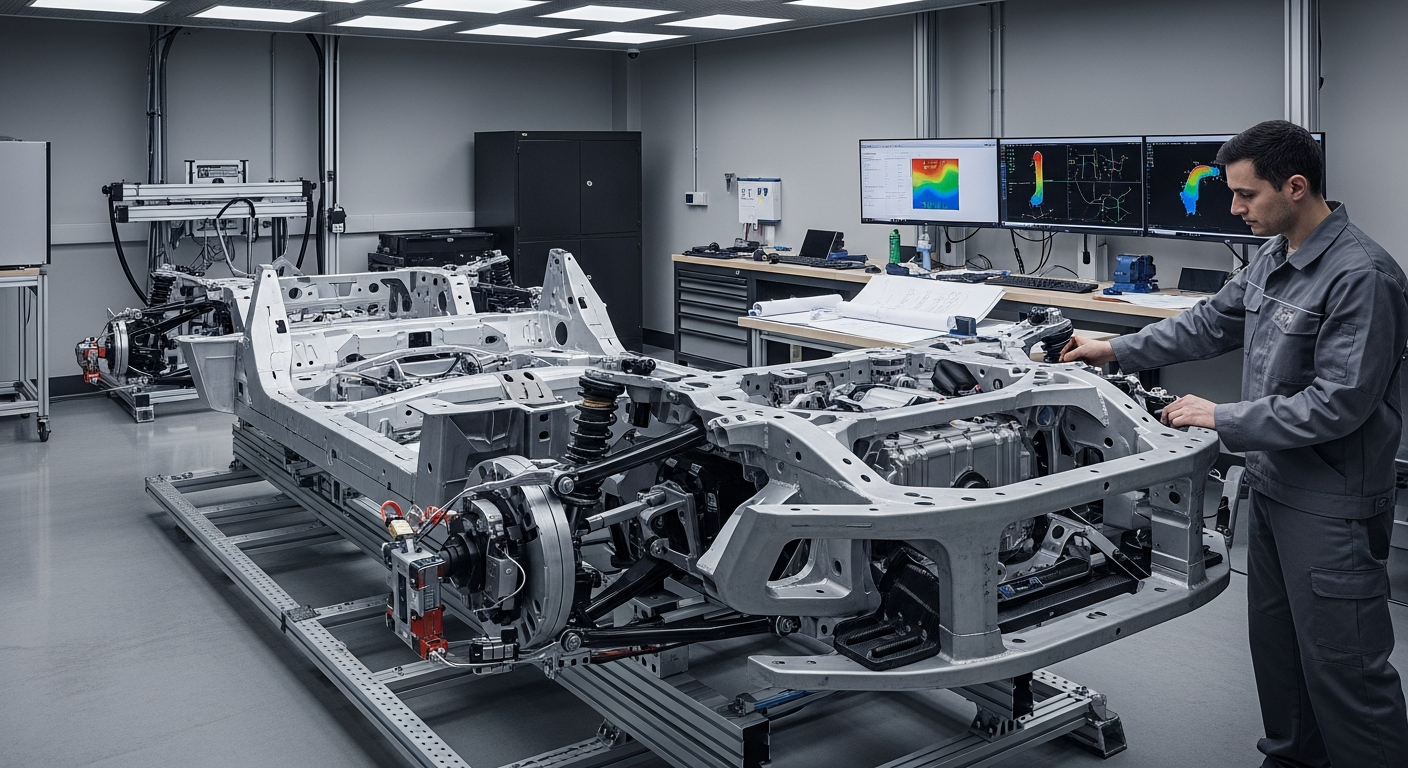

Technological development is a primary driver of innovation, propelling enterprises towards new products, services, and business models. Investing in research and development of emerging technologies allows companies to stay at the forefront of their industries. This continuous pursuit of innovation not only leads to better industrial output but also creates new market opportunities and expands existing ones. Digital twins, for example, allow for virtual testing and optimization of products and processes before physical production, accelerating development cycles and reducing risks.

The adoption of these technologies fosters a culture of continuous improvement and strategic foresight within organizations. By enabling faster iteration, personalized production, and more efficient resource allocation, technology empowers businesses to achieve sustainable growth and respond proactively to evolving consumer preferences and competitive pressures. This strategic integration of technology is crucial for long-term enterprise success.

Enhancing Workflows and Operational Resilience

Modern technologies are instrumental in enhancing workflows and building greater operational resilience within industrial environments. Internet of Things (IoT) devices monitor machinery performance and environmental conditions, providing critical data that helps prevent failures and optimize resource allocation. This real-time monitoring facilitates proactive management of production lines, ensuring smoother workflows and minimizing disruptions.

Furthermore, augmented reality (AR) and virtual reality (VR) tools are increasingly used for training, maintenance, and remote assistance, improving the efficiency and safety of complex tasks. These advancements contribute to a more robust and adaptable operational framework, allowing industries to better withstand unforeseen challenges and maintain consistent industrial output. The optimization of workflows through these tools leads to more consistent production and a higher degree of operational flexibility.

The Future of Industrial Output and Market Dynamics

The ongoing integration of emerging technologies continues to shape the future of industrial output and global market dynamics. As industries become more interconnected and data-driven, the potential for further optimization and innovation grows. Smart factories, characterized by highly automated and self-optimizing production systems, represent the pinnacle of this technological evolution, promising unprecedented levels of efficiency and flexibility. These advancements are not isolated but rather part of a broader trend towards a more digitized and intelligent industrial ecosystem. The ability to leverage these tools for enhanced production, improved resource management, and deeper market insights will be paramount for sustained growth in increasingly competitive global markets. This continuous development transforms not just how products are made, but also how value is created and exchanged across industries.

The impact of emerging technologies on industrial output is transformative, driving unprecedented levels of productivity, efficiency, and resilience. As industries continue to embrace and integrate these innovations, they are poised for sustained growth, greater adaptability, and a stronger position in the global economy. Navigating this evolving technological landscape effectively will be key for businesses aiming to thrive in the future.