Impact of Lightweight Materials on Fuel Efficiency

The automotive industry continually seeks innovative ways to enhance vehicle performance and reduce environmental impact. A significant area of focus is the integration of lightweight materials, which play a crucial role in improving fuel efficiency across various vehicle types. By reducing the overall mass of a vehicle, less energy is required for acceleration and maintaining speed, directly translating into lower fuel consumption and reduced emissions. This approach is fundamental to modern vehicle design, influencing everything from urban mobility solutions to high-performance transportation.

Enhancing Fuel Efficiency Through Material Innovation

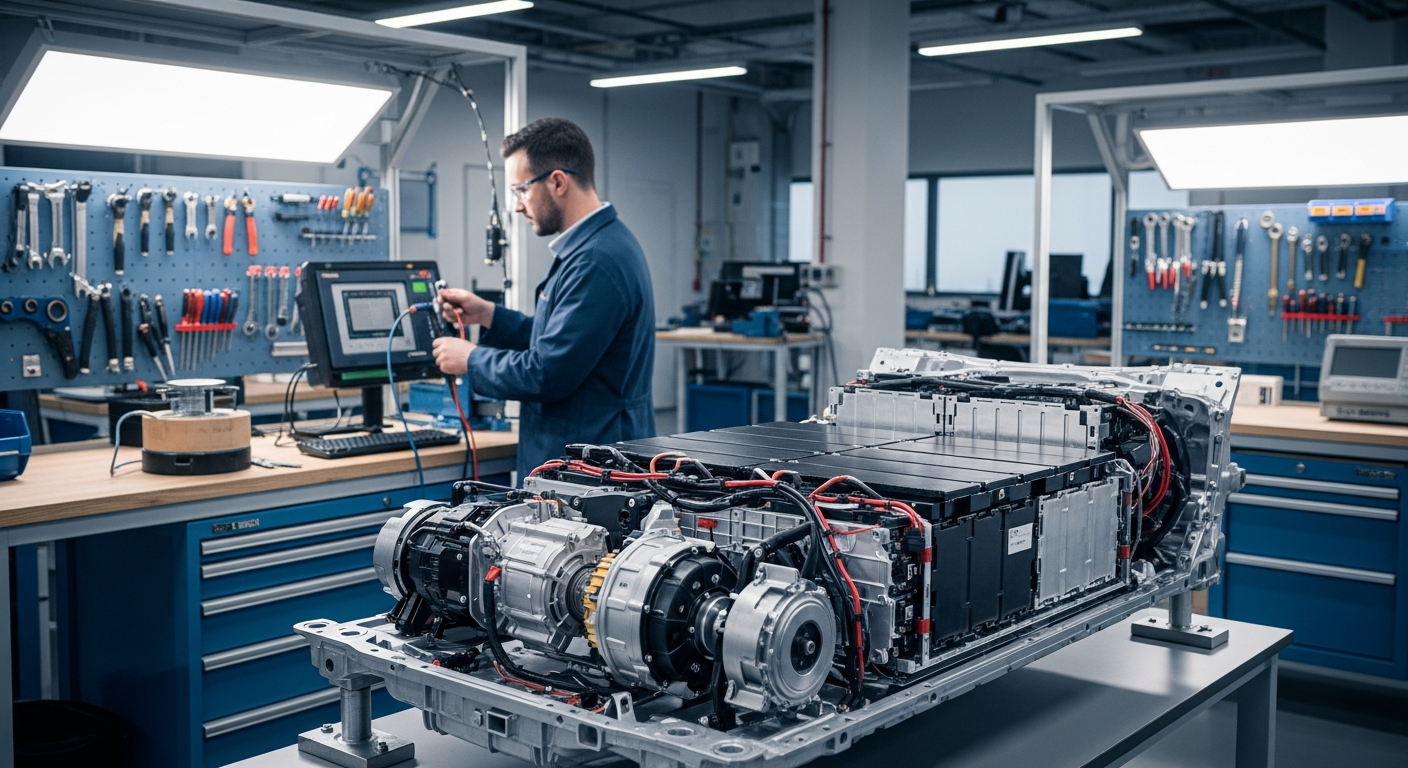

The drive for greater fuel efficiency in modern transportation is a complex challenge, with material innovation standing out as a key solution. Lightweight materials, such as aluminum alloys, carbon fiber composites, and advanced high-strength steels, allow manufacturers to significantly reduce a vehicle’s curb weight without compromising structural integrity or safety. This reduction in mass directly impacts the energy required for propulsion. For internal combustion engines, less weight means less fuel burned per kilometer. In electric and hybrid vehicles, a lighter body extends range and reduces the demands on the battery and electric motors, improving overall system efficiency and performance.

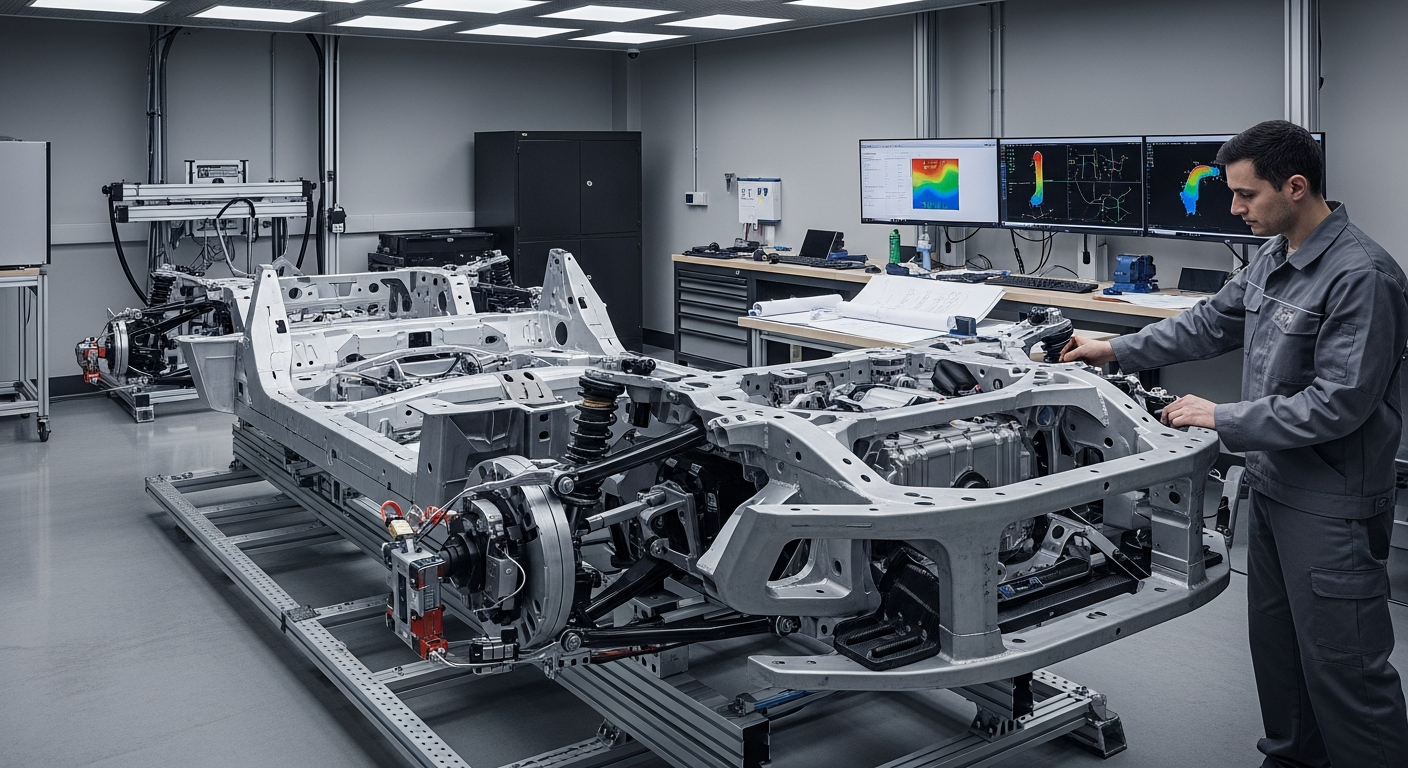

Advanced Engineering and Design Principles

Integrating lightweight materials is not merely about swapping heavy components for lighter ones; it involves advanced engineering and design principles. Modern vehicle design leverages sophisticated simulation tools to optimize material placement, ensuring that strength and rigidity are maintained where needed, while mass is minimized elsewhere. This holistic approach considers the entire vehicle structure, from the chassis and body panels to interior components and engine parts. The seamless integration of these materials requires specialized manufacturing techniques and a deep understanding of mechanics, ensuring that every design choice contributes to both fuel efficiency and the vehicle’s long-term durability.

Material Choices in Vehicle Manufacturing

Vehicle manufacturing has evolved significantly with the advent of new materials. High-strength steel remains a popular choice due to its balance of strength, formability, and cost-effectiveness, with new grades offering increased strength-to-weight ratios. Aluminum alloys are widely used for body panels, engine blocks, and structural components, providing substantial weight savings. Carbon fiber reinforced polymers, while more expensive, offer exceptional strength and stiffness for their weight, making them ideal for high-performance vehicles or specific components where maximum weight reduction is critical. The selection of materials often involves a trade-off between weight savings, cost, manufacturing complexity, and recyclability, all contributing to the vehicle’s overall sustainability profile.

Performance, Safety, and Sustainability Aspects

Beyond fuel efficiency, lightweight materials contribute to enhanced vehicle performance. A lighter vehicle typically exhibits improved acceleration, better handling, and shorter braking distances, contributing to a more dynamic driving experience. Concerns about safety are paramount, and modern lightweight structures are engineered to absorb crash energy effectively, often performing as well as or better than their heavier counterparts. From a sustainability perspective, reducing vehicle weight not only decreases direct fuel consumption and emissions during operation but also lowers the energy required for manufacturing and transportation of materials, contributing to a reduced carbon footprint throughout the vehicle’s lifecycle.

Cost Implications of Lightweight Materials in Production

The adoption of lightweight materials in vehicle manufacturing involves various cost considerations. While these materials can lead to significant long-term savings in fuel consumption, their initial material cost and the complexity of their processing can be higher than traditional steel. Research and development into new alloys and composite manufacturing techniques also represent substantial investments. However, as production scales and technological advancements continue, the cost-effectiveness of these materials is improving. Manufacturers must balance these upfront investments against the benefits of improved fuel economy, regulatory compliance, and consumer demand for more efficient and environmentally friendly vehicles. The overall economic analysis often reveals that the benefits of reduced operational costs and enhanced market competitiveness outweigh the increased manufacturing expenses over the vehicle’s lifespan.

| Material Type | Typical Application | Relative Cost (General Estimate) |

|---|---|---|

| High-Strength Steel | Body structure, chassis | Low to Medium |

| Aluminum Alloys | Body panels, engine blocks | Medium to High |

| Carbon Fiber Composites | Structural components, luxury | High to Very High |

| Magnesium Alloys | Interior frames, brackets | Medium to High |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Directions in Mobility Technology

The future of mobility technology will continue to be shaped by advancements in lightweight materials. As the industry moves towards electric, hybrid, and potentially autonomous vehicles, the importance of weight reduction will only grow. Lighter vehicles will enable longer battery ranges for electric cars, optimize the efficiency of hybrid powertrains, and potentially reduce the size and cost of propulsion systems. Innovation in materials science, coupled with breakthroughs in manufacturing processes like additive manufacturing, promises even lighter, stronger, and more cost-effective solutions. These developments are crucial for achieving ambitious sustainability targets and delivering the next generation of efficient and high-performance transportation.