Leveraging Automation for Enhanced Production Efficiency

In today's dynamic business environment, organizations across various sectors are increasingly recognizing the transformative power of automation. Integrating automated systems and processes can significantly enhance operational capabilities, leading to substantial improvements in how goods are produced and services are delivered. This strategic shift is not merely about reducing manual labor but about redesigning workflows to achieve greater precision, speed, and overall efficiency, positioning businesses for sustained growth and competitiveness on a global scale.

Understanding Automation in Enterprise Operations

Automation extends beyond simple task execution, becoming a foundational element in modern enterprise operations. It involves deploying technology to perform routine, repetitive, or complex tasks with minimal human intervention. This can range from automated data entry and report generation to sophisticated robotic systems on a factory floor or AI-driven analytics platforms. By embedding automation into core enterprise functions, businesses can streamline processes, reduce human error, and free up their workforce to focus on more strategic, creative, and value-added activities. The strategic implementation of automation technology plays a crucial role in optimizing resource allocation and improving overall operational flow across an organization.

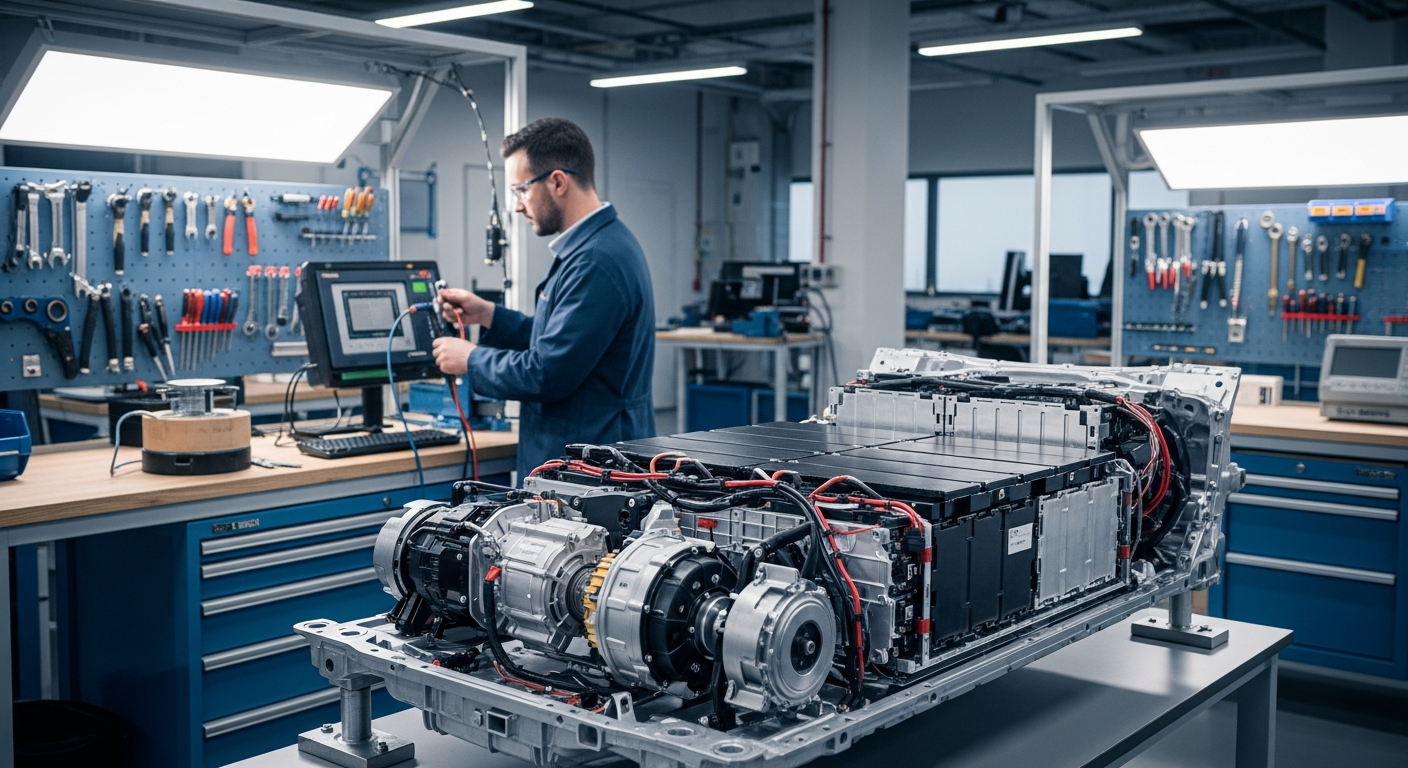

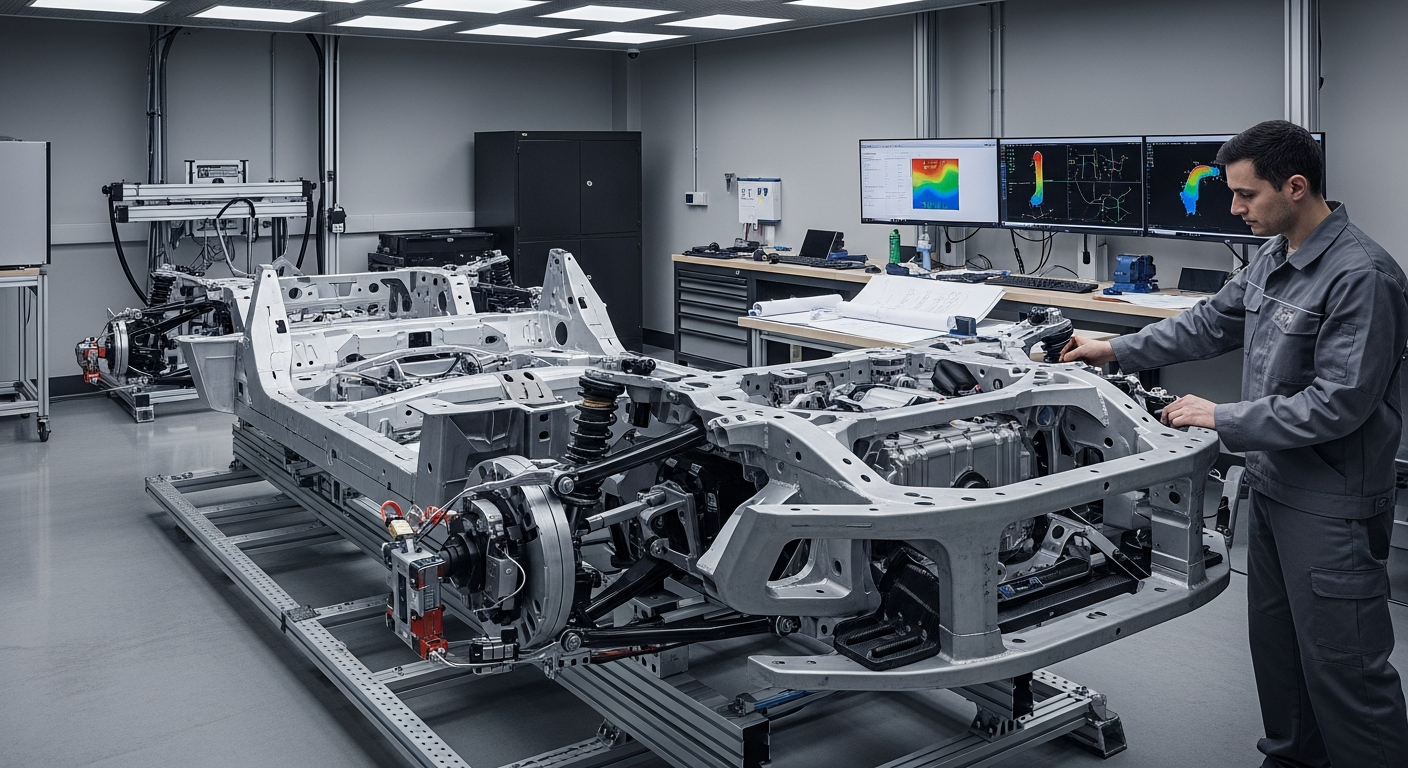

Impact on Manufacturing and Production Efficiency

For the manufacturing sector, automation is a critical driver of production efficiency. Automated machinery and systems can operate continuously, often with greater speed and accuracy than manual processes. This leads to higher output volumes, consistent product quality, and reduced waste. From assembly lines managed by industrial robots to automated quality control systems, technology minimizes bottlenecks and enhances throughput. The precise control offered by automation also allows for better utilization of raw materials and energy, contributing to both cost savings and more sustainable production practices.

Streamlining Logistics and Supply Chain Management

Automation plays a pivotal role in optimizing logistics and supply chain management, transforming how goods are moved, stored, and tracked. Automated warehouses utilizing robotic picking systems, autonomous guided vehicles (AGVs), and sophisticated inventory management software can significantly accelerate order fulfillment and improve inventory accuracy. Furthermore, automation in transportation, such as route optimization software and predictive analytics for demand forecasting, helps create more resilient and responsive supply chains. This integration allows companies to react swiftly to market changes and disruptions, ensuring timely delivery and reducing operational costs.

Fostering Innovation and Strategic Growth

By automating routine and time-consuming tasks, businesses can reallocate human capital towards innovation and strategic initiatives. Employees, freed from mundane duties, can dedicate their skills to problem-solving, product development, market research, and customer relationship building. This shift fosters a culture of innovation, empowering teams to explore new ideas and develop solutions that drive strategic growth. Automation provides the underlying efficiency that allows an enterprise to invest more resources into long-term development and competitive differentiation.

Workforce Development and Sustainability through Automation

The integration of automation necessitates a focus on workforce development. While some tasks become automated, new roles emerge that require oversight, maintenance, and programming of these advanced systems. This creates opportunities for upskilling and reskilling the existing workforce, transforming job functions rather than simply eliminating them. From a sustainability perspective, automation can lead to more efficient use of resources, reduced energy consumption in optimized processes, and less material waste, contributing to environmentally responsible business practices and long-term operational resilience.

| Product/Service | Provider | Key Features/Benefits |

|---|---|---|

| Robotic Process Automation (RPA) | UiPath, Automation Anywhere, Blue Prism | Automates repetitive digital tasks, improves accuracy |

| Industrial Automation Systems | Siemens, Rockwell Automation, ABB | Controls and monitors manufacturing processes, enhances production |

| Warehouse Automation Solutions | Dematic, KUKA, Swisslog | Automated storage, retrieval, and sorting, boosts fulfillment speed |

| Enterprise Resource Planning (ERP) with Automation | SAP, Oracle, Microsoft Dynamics | Integrates business processes, centralizes data, optimizes resources |

| AI-Powered Analytics Platforms | Google Cloud AI, IBM Watson, SAS | Provides data analysis, predictive insights, supports informed decisions |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Embracing automation is a critical step for organizations aiming to achieve enhanced production efficiency and maintain a competitive edge. From optimizing manufacturing lines and streamlining supply chains to fostering innovation and developing a future-ready workforce, automation offers multifaceted benefits. Its strategic implementation allows businesses to operate with greater precision, speed, and resilience, ultimately paving the way for sustainable growth in an evolving global marketplace.