Navigating Supply Chain Complexities in Modern Industry

Modern industry faces intricate supply chain challenges that demand strategic foresight and robust solutions. From global disruptions to evolving consumer demands, businesses worldwide are grappling with the need for greater visibility, agility, and resilience within their operational frameworks. Understanding these complexities is the first step toward building more adaptable and efficient supply networks that can withstand unforeseen events and support sustainable growth in a dynamic economic landscape.

Understanding Modern Supply Chain Challenges

The contemporary global economy presents an array of challenges for enterprise supply chains. Businesses must contend with geopolitical shifts, trade policy changes, and the inherent volatility of international markets. These factors contribute to an environment where the seamless flow of goods, from raw materials through manufacturing and production to final delivery, can be easily disrupted. Achieving supply chain resilience requires a deep understanding of these external pressures and the development of proactive strategies to mitigate risks and maintain operational continuity.

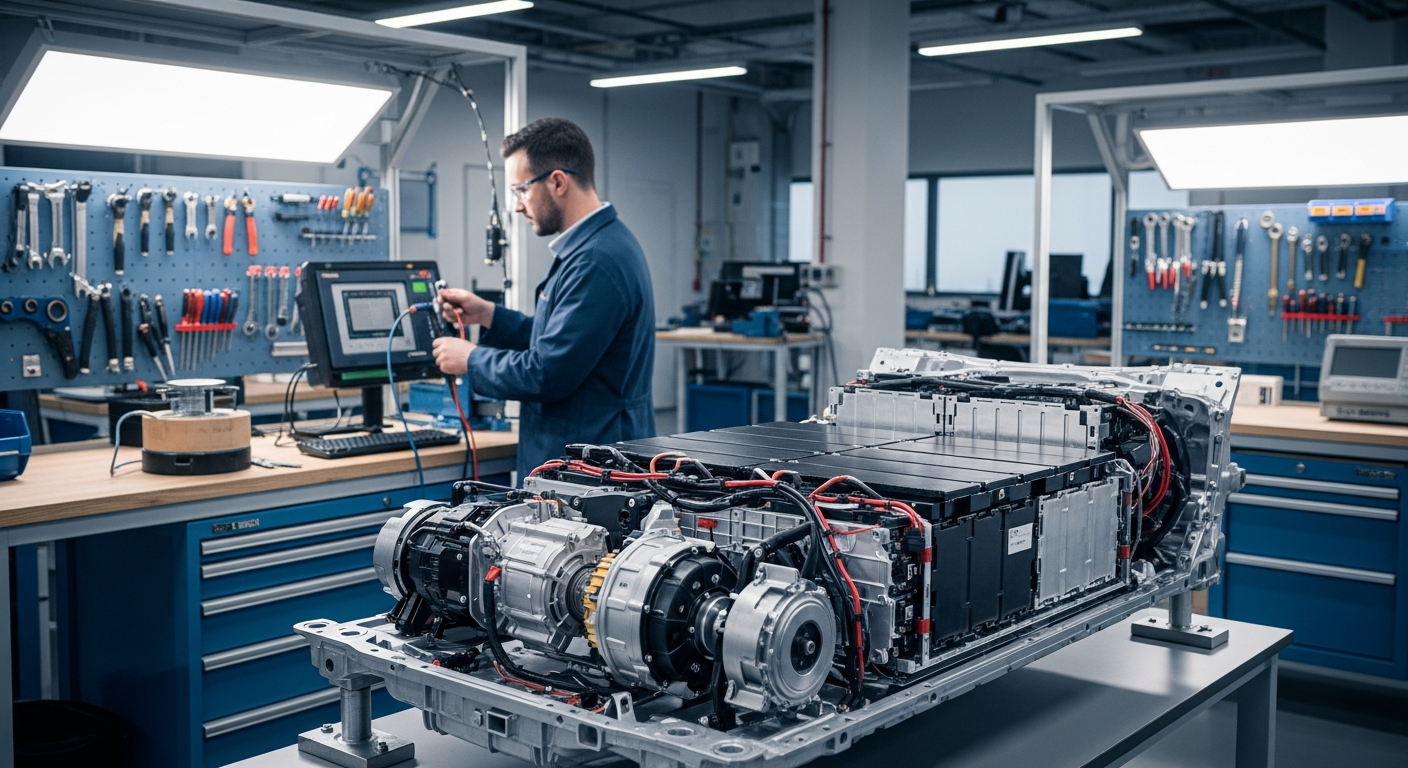

Leveraging Technology for Enhanced Supply Chain Efficiency

Technology plays a pivotal role in addressing the complexities of modern supply chains. The adoption of digital tools and advanced analytics can significantly improve efficiency and decision-making. Automation, through robotics and intelligent systems, streamlines repetitive tasks in manufacturing and logistics, reducing human error and accelerating processes. Furthermore, the integration of data analytics provides valuable insights into performance, demand forecasting, and potential bottlenecks, enabling companies to innovate and optimize their supply networks. This digital transformation is crucial for maintaining a competitive edge and fostering sustainable growth.

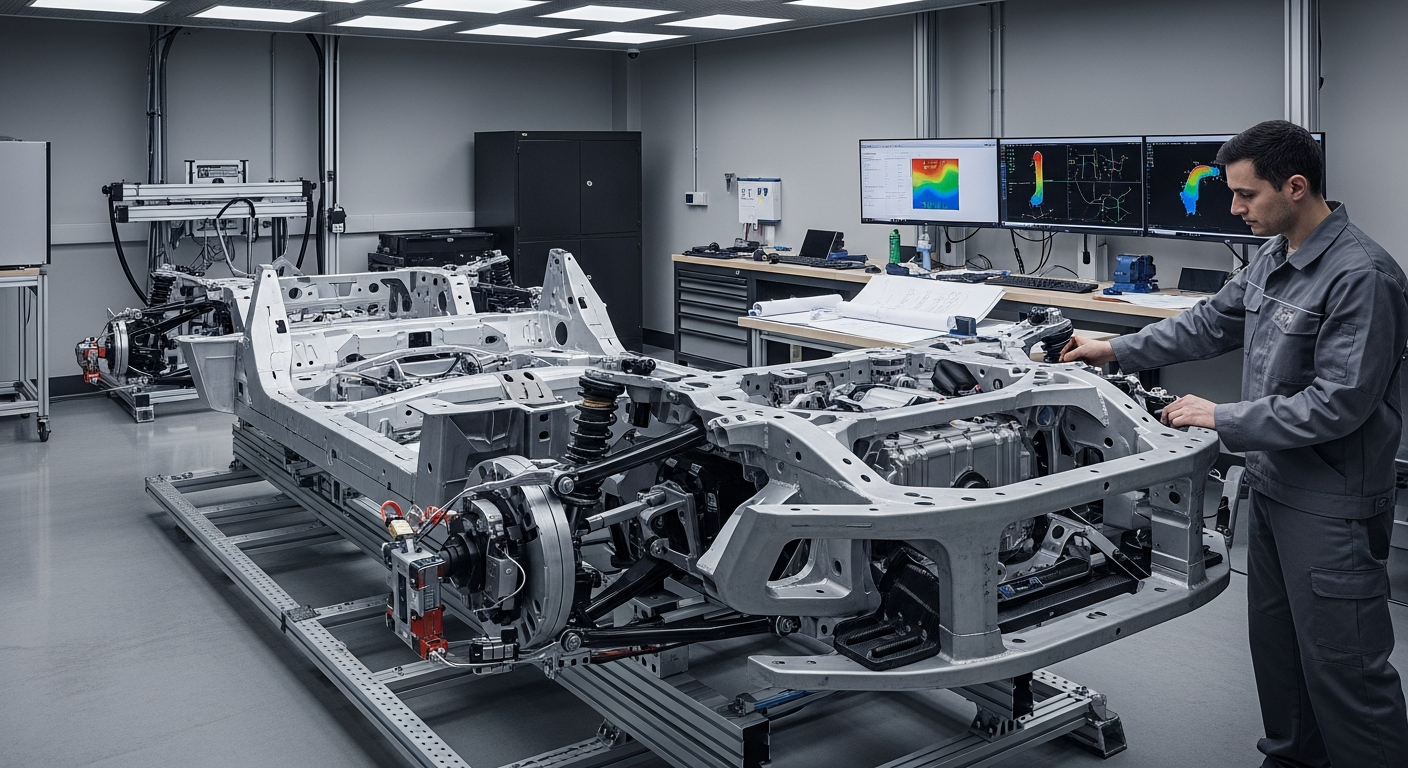

Optimizing Manufacturing and Logistics Operations

Optimizing manufacturing and logistics operations is fundamental to a well-functioning supply chain. This involves refining production processes, managing inventory effectively, and ensuring timely transportation of goods. Companies are increasingly focusing on lean principles and continuous improvement methodologies to eliminate waste and enhance overall operational efficiency. Effective management of these core functions directly impacts cost, quality, and delivery times, which are critical for customer satisfaction and market position. A well-optimized operation contributes significantly to the overall health and responsiveness of the supply chain.

Developing Strategic Approaches for Supply Chain Resilience

Building resilience into a supply chain requires a comprehensive strategy that spans across all levels of management. This involves diversifying supplier bases, investing in local supply capabilities, and developing contingency plans for various disruption scenarios. A resilient supply chain is one that can absorb shocks, adapt quickly, and recover efficiently, minimizing the impact on production and customer commitments. Workforce training and development are also key components, ensuring that teams are equipped with the skills to navigate challenges and implement innovative solutions. Such strategic foresight is vital for long-term growth and stability in an unpredictable global economy.

| Solution Type | Key Investment Areas | Estimated Investment Range (General) |

|---|---|---|

| Supply Chain Management Software | Licensing, Implementation, Customization, Training | $50,000 - $5,000,000+ |

| Automation & Robotics | Hardware, Software, Integration, Maintenance | $10,000 - $1,000,000+ per unit/system |

| Data Analytics & AI | Software Platforms, Data Scientists, Infrastructure | $20,000 - $2,000,000+ |

| Consulting & Strategy Development | Expert Fees, Workshops, Project Management | $10,000 - $500,000+ |

| Workforce Training & Development | Course Fees, Materials, Internal Resources | $5,000 - $100,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Investment in Supply Chain Solutions: A General Overview

Addressing supply chain complexities often requires significant investment in technology, infrastructure, and human capital. The cost of implementing advanced supply chain management software, for instance, can vary widely based on the scale of the enterprise and the level of customization required. Similarly, the adoption of automation and robotics in manufacturing and logistics involves initial capital outlay for equipment and integration, alongside ongoing maintenance costs. While these investments represent a financial commitment, they are often offset by long-term gains in efficiency, reduced operational risks, and improved overall growth. Evaluating the return on investment (ROI) for such initiatives is a critical part of the strategic planning process, ensuring that resources are allocated effectively to enhance global supply chain capabilities.

Navigating the intricate landscape of modern industrial supply chains requires a multi-faceted approach, combining technological innovation with robust strategic planning. By prioritizing efficiency, fostering resilience, and continually optimizing operations, businesses can transform challenges into opportunities for sustained growth and competitive advantage. The commitment to understanding and adapting to global and economic shifts is paramount for any enterprise aiming to thrive in today’s dynamic industrial environment.