Sustainable Practices in Modern Production Management

Modern production management is increasingly integrating sustainable practices to address environmental concerns, optimize resource use, and meet evolving consumer and regulatory demands. This shift involves a comprehensive approach that re-evaluates traditional operational methods, supply chain networks, and technological applications. Embracing sustainability is no longer just an ethical choice but a strategic imperative that can drive efficiency, foster innovation, and enhance long-term business resilience in a competitive global market.

Integrating Sustainability into Modern Operations and Manufacturing

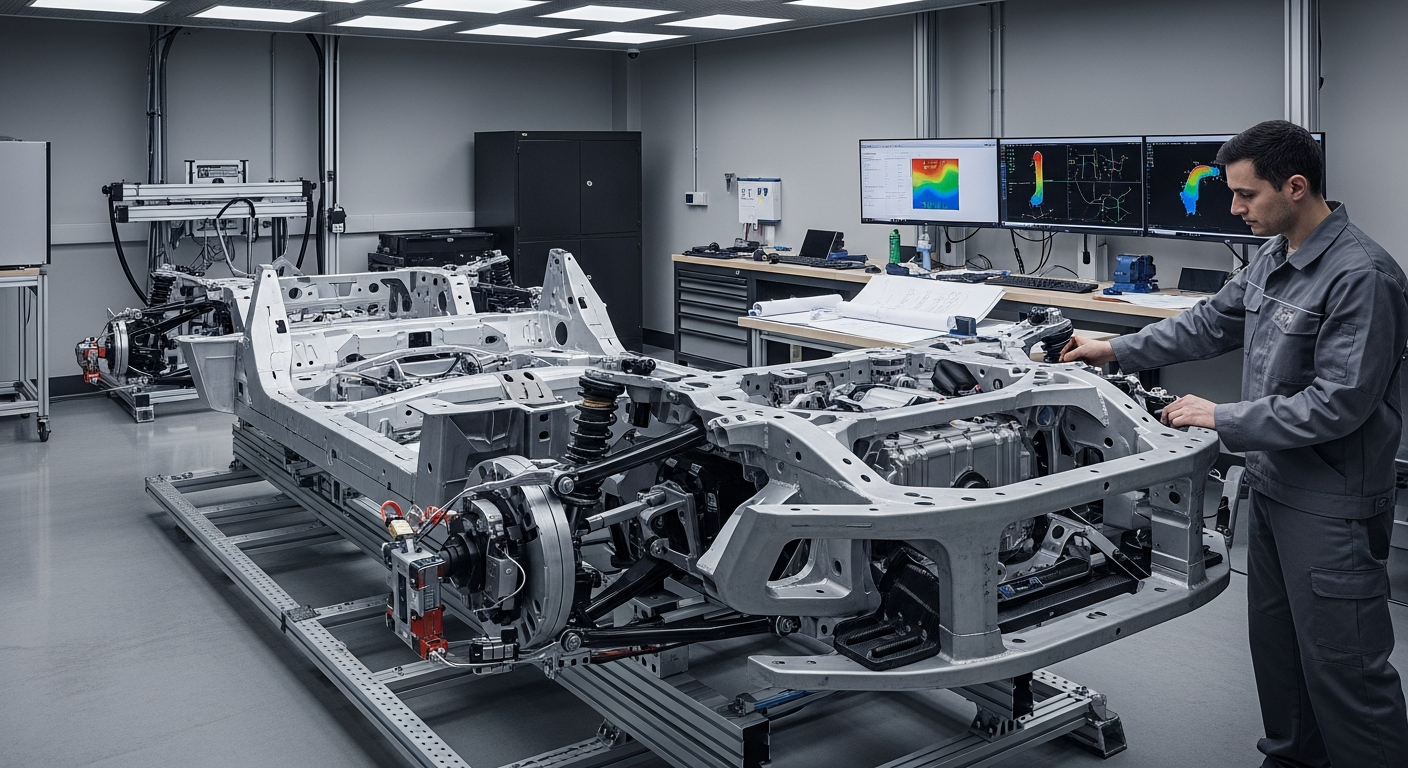

Integrating sustainability into core operations and manufacturing processes is fundamental for modern enterprises. This involves a systematic re-evaluation of how products are designed, produced, and delivered to minimize environmental impact while maintaining economic viability. Key aspects include adopting circular economy principles, where materials are kept in use for as long as possible through recycling, reuse, and remanufacturing. Optimized production schedules, lean manufacturing techniques, and efficient resource management are crucial for reducing waste, energy consumption, and raw material usage. Companies are increasingly investing in process improvements that not only cut down on emissions and pollution but also enhance overall operational efficiency and product quality.

Enhancing Supply Chain Resilience and Green Logistics

A sustainable supply chain is characterized by its resilience and its commitment to environmentally friendly logistics. This involves scrutinizing every stage of the supply network, from raw material sourcing to final product delivery. Sustainable supply chain management focuses on ethical sourcing, ensuring that materials are procured responsibly and that suppliers adhere to fair labor and environmental standards. Green logistics initiatives aim to reduce the carbon footprint associated with transportation by optimizing routes, utilizing more fuel-efficient vehicles, and exploring multimodal transport options. Furthermore, implementing reverse logistics systems for product returns, repairs, and end-of-life recycling contributes significantly to minimizing waste and enhancing resource recovery across the global commerce landscape.

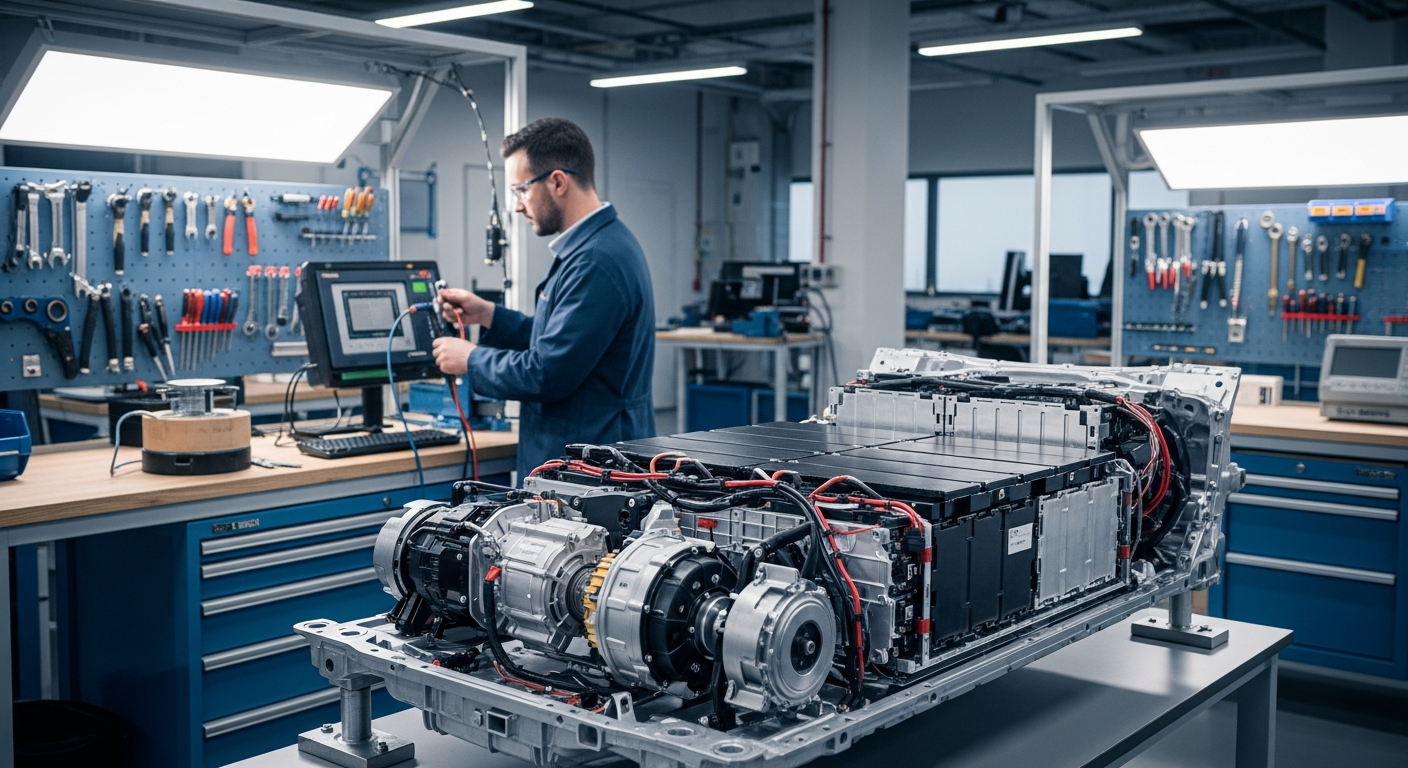

Leveraging Technology and Automation for Eco-efficient Production

Technology and automation play a pivotal role in achieving eco-efficient production. Advanced digital tools, such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, enable real-time monitoring and optimization of production processes, leading to significant reductions in energy and material waste. Automation can streamline operations, reduce human error, and enhance precision, contributing to higher quality products and fewer defects. Predictive maintenance, powered by AI, minimizes downtime and extends the lifespan of machinery, further improving resource efficiency. Innovations in smart factory concepts allow for dynamic adjustments to production lines, ensuring that resources are utilized optimally and environmental impact is continuously minimized.

Strategic Management for Innovation and Resource Efficiency

Strategic management is essential for driving innovation and fostering resource efficiency within an enterprise. This involves top-down commitment to sustainability goals, integrating them into the core business strategy, and fostering a culture of continuous improvement. Leadership must champion research and development (R&D) efforts for creating sustainable products and processes, encouraging employees to identify and implement eco-friendly solutions. Effective management also includes setting measurable targets for environmental performance, conducting regular audits, and transparently reporting progress. By embedding sustainability into strategic planning, businesses can unlock new market opportunities, enhance their brand reputation, and build a more resilient and future-proof organization.

Investment Considerations for Sustainable Production Practices

Adopting sustainable practices in production management typically involves various investment areas, which can vary significantly depending on the industry, company size, and the specific initiatives undertaken. Initial expenditures might include upgrading machinery for greater energy efficiency, implementing advanced waste reduction and recycling systems, or investing in renewable energy sources like solar panels for manufacturing facilities. Companies also allocate resources for research and development into sustainable materials and processes, as well as for employee training programs focused on green practices. Furthermore, achieving various sustainability certifications often incurs costs for audits and compliance.

While these upfront investments can be substantial, they often lead to long-term operational savings through reduced energy consumption, lower waste disposal costs, and optimized resource utilization. The return on investment can also manifest in enhanced brand reputation, increased market appeal for environmentally conscious consumers, and improved regulatory compliance, potentially mitigating future fines or penalties.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Driving Global Market Growth through Sustainable Enterprise

Embracing sustainable practices is a powerful driver for global market growth and enhances an enterprise’s competitive edge. Consumers worldwide are increasingly prioritizing environmentally and socially responsible products, creating new market segments and opportunities for businesses that demonstrate a commitment to sustainability. A strong sustainability profile can improve brand perception, build customer loyalty, and attract investment from socially conscious investors. Moreover, adhering to international environmental regulations and standards can facilitate access to new global markets, while proactive innovation in sustainable solutions can differentiate a company from its competitors. By integrating sustainability into their core strategy, businesses can achieve robust and resilient growth in an evolving global economy.

Conclusion

Sustainable practices in modern production management are integral to navigating the complexities of today’s global industry. By integrating sustainability into every facet of operations, supply chain, and strategic management, businesses can achieve greater efficiency, foster innovation, and build resilience. Leveraging technology and making informed investments in green initiatives are key to realizing both environmental stewardship and long-term economic prosperity. This holistic approach not only addresses pressing ecological concerns but also positions enterprises for sustained growth and a competitive advantage in the dynamic global market.